You’ve found an old warehouse ideal for growing. It has water, a loading dock, a pool of potential employees, not far from retail customers, a sweetheart deal from the building owner, and local SMB tax credits to boot! With a little luck from contractors and building inspectors, you could be harvesting within a year.

How Much Power Do I Need?

What about power? That 2 x 200A panel provides 400 amps of power – plenty for what used to be here — but what about the high-wattage systems needed for an indoor grow? These facilities consume far more electricity than you think. HVAC, controllers and sensors, computers, fertigation pumps, fans, CO2 and air-exchange, exhaust systems, production equipment and more. We’ve not even discussed lighting – the most important infrastructural equipment decision you make toward the success of your farm.

Going forward, will you go vertical? What if you expand into the neighboring space? What if tomorrow’s growing equipment requires even more power than today? What if you want to add micro-grid to offset your ever-rising electrical bills?

Is your electrical infrastructure ready to grow and adjust with you?

Three Things to Consider When Powering Your Facility

Here are some thoughts to keep in mind when planning your retrofit facility:

- Code mandates you cannot exceed 80% of your load. Meaning, you don’t have 400 amps to work with, but 320. Depending on the room size, that could be two flower rooms and you’re maxed out. And don’t overload! Make sure to carefully sequence operations to never exceed this draw or you’ll be shut down.

- Transformers. You may need to install one to meet your new energy requirements. Today’s supply chain means utility-provided and utility-approved “dry” transformers have an 18-month wait. You could buy one online, but these are referred to as “wet” (requiring quarterly maintenance, oil changes, form submission to ensure compliance, etc.) and not serviced by the utilities. Meaning, you must become trained on the transformer and properly file the reports every quarter or hire a company in to do it. If you don’t follow the rules, the utility shuts off your power.

- Permits. If going this alone, you’ll need architectural drawings and engineer calculations, which can easily surpass $50K. These people know the approval process and how to get things done on your behalf.

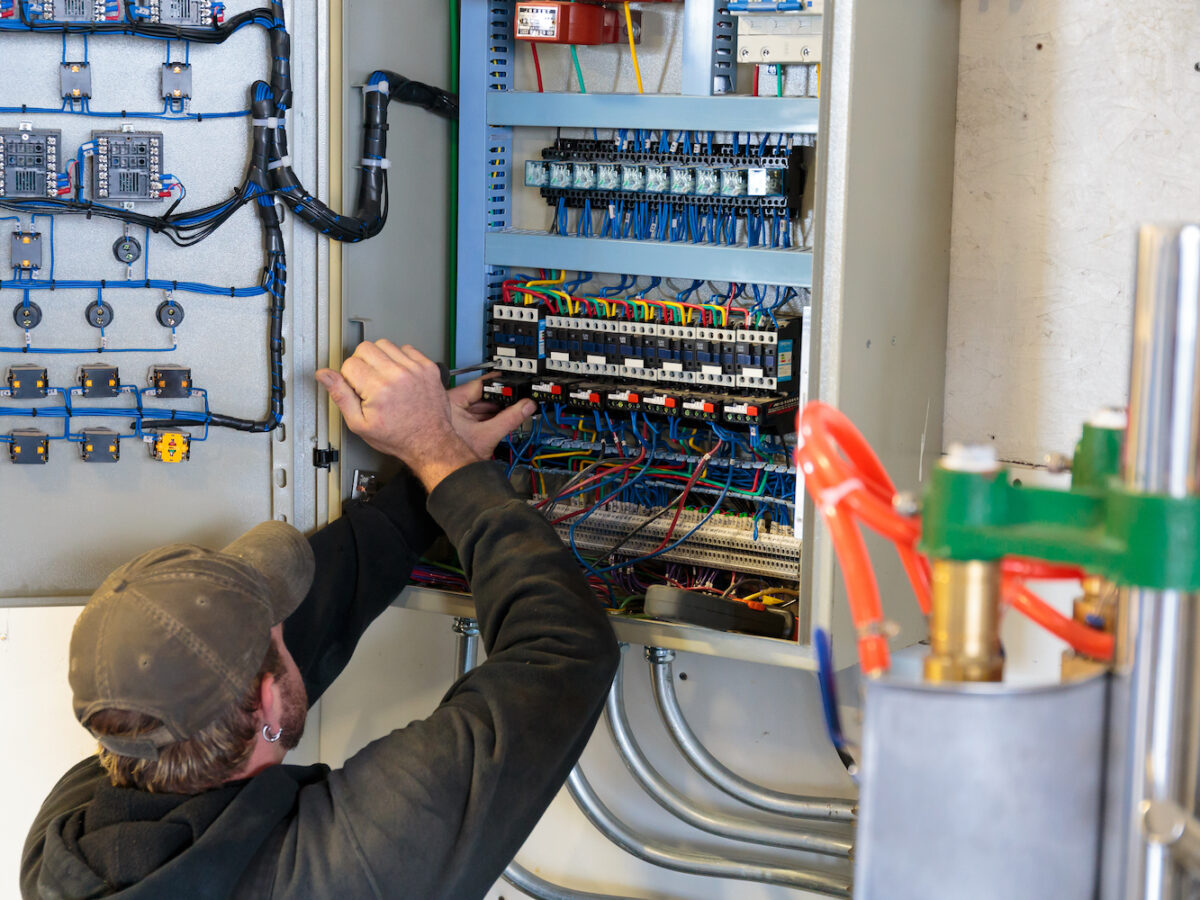

We’ve found that facilities that cut corners are often not to code and require experts to fix it. The problem is that most established electrical contractors won’t touch it. Untangling poorly installed, not-to-code systems presents risks they won’t to take on. Too much other business to be had.

Your power system undergirds your entire facility. This is NOT the place to cut corners. Let UYS help ensure your new facility is prepared to today’s challenges – and tomorrow. By the time you’ve cut all these corners, it honestly makes more sense to have the professionals do it right out of the gate.